A1 RMC BUILDCON

Plant 1

Khasra number - 152, OPP- GAUTAM BUDDH UNITVERSITY,

VILLAGE-GHARBARA, GREATER NOIDA, UP-201310

Plant 2

Khasra number -758, Village Dasna, Wave City Gate, NH 24,

Dasna, Ghaziabad, Uttar Pradesh - 201015

9711881433

Welcome to A1 RMC Buildcon

The Strength That Never End’s

A1 Concrete is a leading ready mix concrete plant dedicated to providing superior quality concrete solutions for all your construction needs. With years of experience in the industry, we pride ourselves on our commitment to excellence, reliability, and customer satisfaction.

Quality Assurance

Our concrete is produced using high-quality materials and undergoes rigorous testing to ensure it meets the highest standards

Eco-Friendly

We are committed to sustainability and employ eco-friendly practices in our production processes

Competitive Pricing

We offer affordable rates without compromising on quality or service.

Customer-Centric Approach

Our team is dedicated to providing exceptional service and support from start to finish.

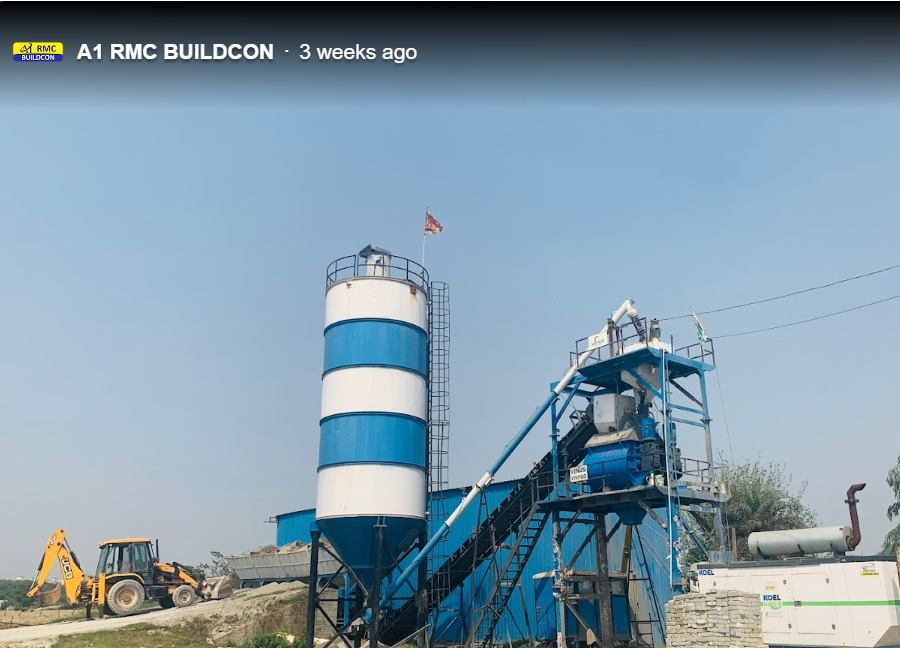

Our Plants

Plant 1

Khasra number -152, OPP- GAUTAM BUDDH UNITVERSITY, VILLAGE-GHARBARA, GREATER NOIDA, UP-201310

Plant 2

Khasra number -758, Village Dasna, Wave City Gate, NH 24, Dasna, Ghaziabad, Uttar Pradesh – 201015

Customer's reviews

“I highly recommend the A1 RMC Buildcon for their exceptional service and high-quality concrete. Their knowledgeable team delivers on time with skilled drivers and a wide variety of mixes to choose from. They provide excellent customer service and are a trusted partner for any construction project.”

Vinay Kumar

“I highly recommend this A1 RMC Buildcon for their exceptional service, high-quality concrete, and reliable delivery. Their knowledgeable team and flexible approach make them a great partner for any construction project.”

Ramesh Singh

.

“I have consistently received outstanding service from this Ready Mix concrete supplier. Their team is highly professional, always willing to help and provide expert advice. Their concrete is of the highest quality and delivered on time, making them a trusted and reliable partner for any construction project.”

Jatin Taneja

“I’ve had a great experience with A1 BuildCon. Their team is knowledgeable, supportive, and ensures timely delivery of top-quality concrete, making them a dependable choice for construction needs.”

Sachin Tyagi

What we are :

A1 RMC BUILDCON The Most Trusted Ready-Mix Concrete Provider. We are the leading ready-mix concrete manufacturer in Greater Noida & Ghaziabad area, providing quality services to both B2B and B2C customers. Our commitment to quality and customer satisfaction has earned us a reputation as the most reliable ready-mix concrete provider. Quality You Can Trust : Our plant consists of silos and bins for storing raw materials like cement, sand, water, fly ash, admixtures etc., which allows us to produce high quality concrete. We also use state-of-the-art technology to ensure that all our products are up to the highest standards. We offer a range of convenient services such as on-time delivery, easy payment options and personalized customer service.

Ready Mix Concrete

High-Performance Concrete,Customized Mix Designs.

On-Time Delivery

State-of-the-art fleet of trucks ensuring prompt and efficient delivery.

Expert Consultation

Professional advice from our experienced team of Engineers and Technicians.